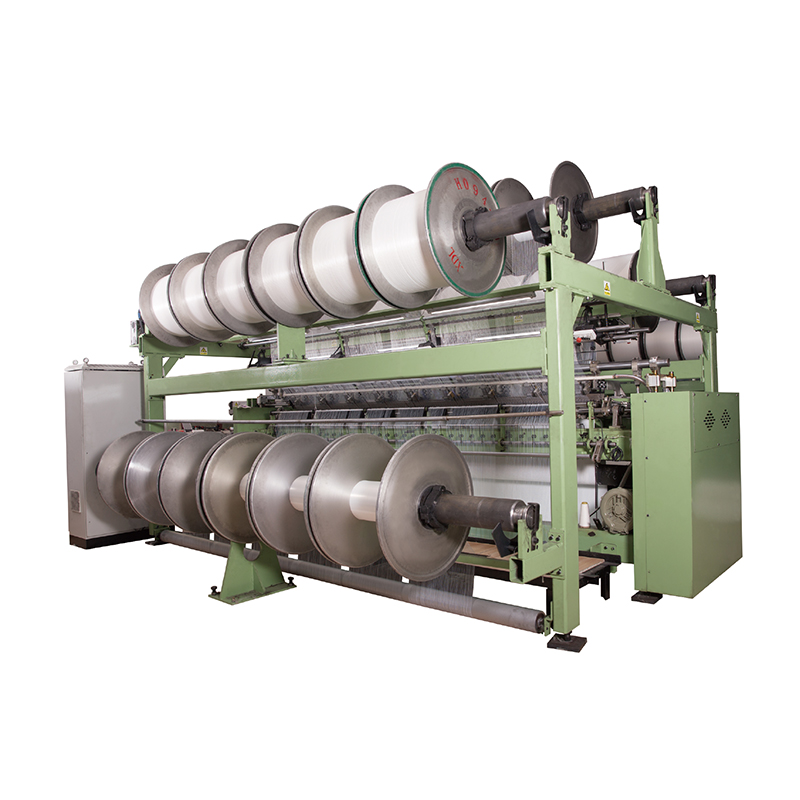

Factory made hot-sale Matrix Weight - YRS3-M-F-II Chopped Biaxial Warp Knitting Machine – Yixun

Factory made hot-sale Matrix Weight - YRS3-M-F-II Chopped Biaxial Warp Knitting Machine – Yixun Detail:

*Used for producing full width weft insertion chopped mat and composite fabric

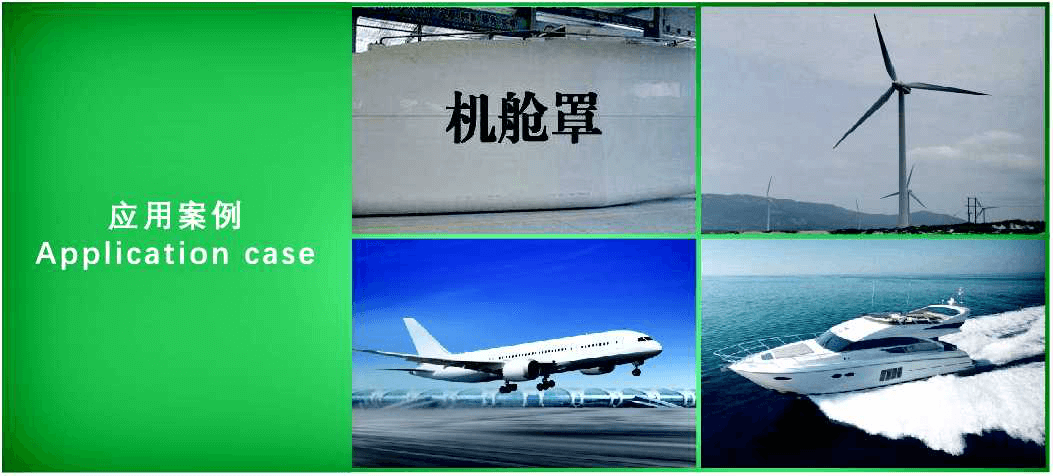

Application Case

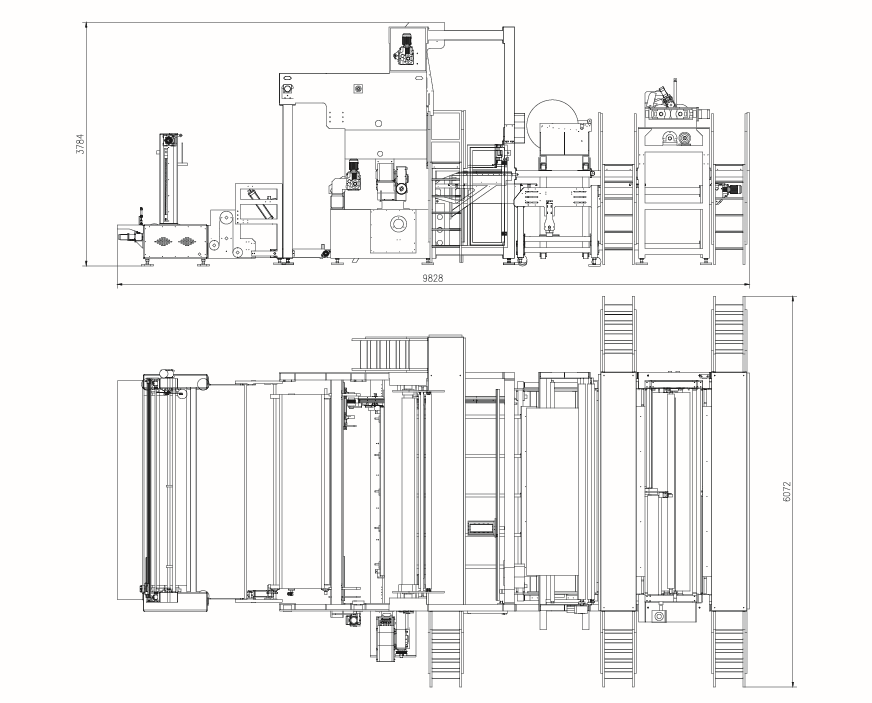

General assembly drawing

Specifications

| Width | 103 inch |

| Gauge | E7 |

| Speed | 50-1000r/min (The specific speed depend the products.) |

| Bar Number | 2 Bars |

| Pattern Drive | Split Pattern Disc |

| Warp Beam Support | 30 inches beam.EBC |

| Take-up Device | Electronic Take-up |

| Batching Device | Electronic Batching |

| Chopped Device | 1 Chopped Device,Servo System Controlling. |

| Weft-insertion System | Weft Insertion,Servo System Controlling. |

| Power | 28kW |

| This type* s machine could be personal designed |

Product Video

Your browser does not support video tags.

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Factory made hot-sale Matrix Weight - YRS3-M-F-II Chopped Biaxial Warp Knitting Machine – Yixun , The product will supply to all over the world, such as: Nairobi, Bangkok, Mombasa, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

Write your message here and send it to us