METHODS MACHINE TOOLS CAN PARTNER

WITH YOU EVERY STEP OF THE WAY.

From selecting and configuring the right

machine for your job to helping you finance the purchase that generates noticeable profits.

-

YRS3-M Biaxial Warp Knitting Machine

*This Machine Is Mainly ...

-

YRS3-M-F-II Chopped Biaxial Warp Knitting Machine

*Used for producing full...

-

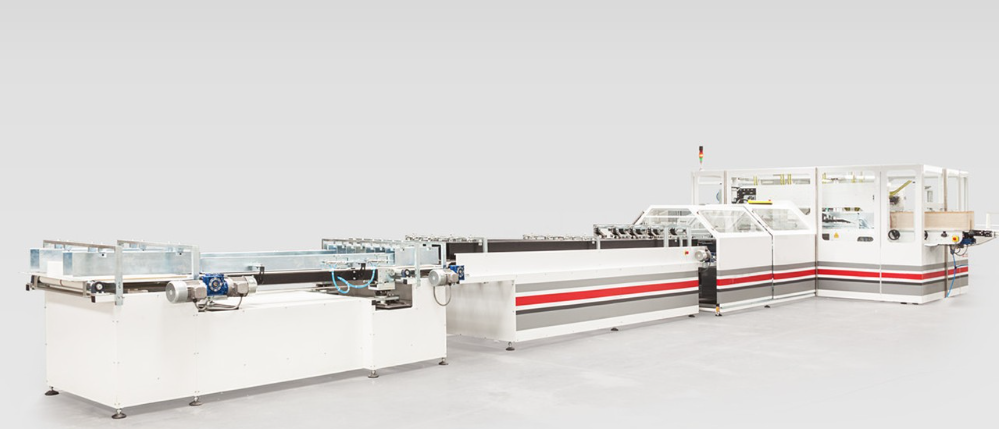

FC Chopped Stitch-bonding Machine

*This machine is used for p...

-

YRS3-N-F-I Type Chopped Biaxial Warp Knitting M...

*Mainly applied for wind po...

-

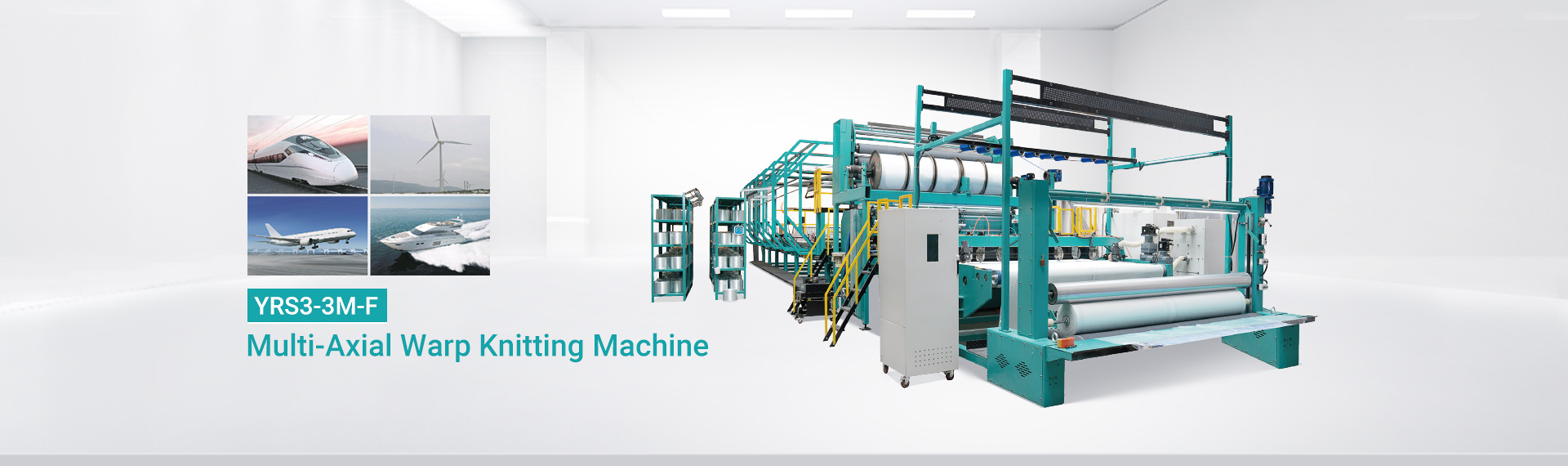

YRS3-3M-F Multi-axial Warp Knitting Machine

*Used for producing full...

-

FC(ll)Chopped Stitch Bonding Machine

*This machine is used fo...

-

FCD Double Chopped Stitch Bonding Machine

*This machine is used for p...

-

FCM Chopped Biaxial Warp Knitting Machine

*This machine is used for p...

-

FB Fiber-web Stitch-bonding Machine

*Used for producing stit...

-

YRS3-M-F-II Chopped Biaxial Warp Knitting Machine

*Used for producing full...

-

FC Chopped Stitch-bonding Machine

*This machine is used for p...

-

YRS3-3M-F Multi-axial Warp Knitting Machine

*Used for producing full...

Product Video

MISSION

STATEMENT

DANYANG YIXUN MACHINERY CO., LTD-is a professional manufacturer to produce multiaxial/biaxial warp knitting machine,stitch bonding warp knitting machine and towel warp knitting machine for glass fibre,combination mat,chopped strand mat rovings and

Sincerely recruit agents for each country

ATTN:Cana

WhatsApp/Wechat/TEL:+86 13401554989

Email: cana@yixun-machinery.com

recent

NEWS

-

What is the stitch bonding technique?

Stitchbonding is a method used in textile manufacturing to create fabrics by mechanically interlocking fibers using various stitching methods. The technology can be used to produce a variety of fabrics with different textures, thicknesses and stretch properties. It is co...

-

Merry Christmas:What machine is used for warp knitting?

There is no doubt that the machine used for warp knitting is called a warp knitting machine. This type of machine is specifically designed to produce knitted fabrics using parallel yarns, called "warps." Warp knitting machines use different mechanisms compared to weft kn...

-

What is the differense between warp knitting machine and wert knitting machine?

The main difference between a warp knitting machine and a weft knitting machine is the direction of yarn movement and fabric formation. Warp knitting machine: In a warp knitting machine, the yarns are stretched parallel to the length of the fabric (warp direction) and in...

-

Warp knitting machines revolutionize the textile industry, enabling efficient production and multifunctional design

In recent years, with the introduction of advanced warp knitting machines, the textile industry has undergone major changes. These machines revolutionized the production process by increasing efficiency, speed and versatility. In this news article, we will explore the ma...

-

Rapid advances in pultrusion equipment revolutionize composite manufacturing

The pultrusion process has become the primary method for manufacturing high-strength, lightweight, and corrosion-resistant fiber-reinforced polymer (FRP) composites. As pultrusion equipment technology continues to advance, the industry is witnessing a shift in composite ...

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu